Products

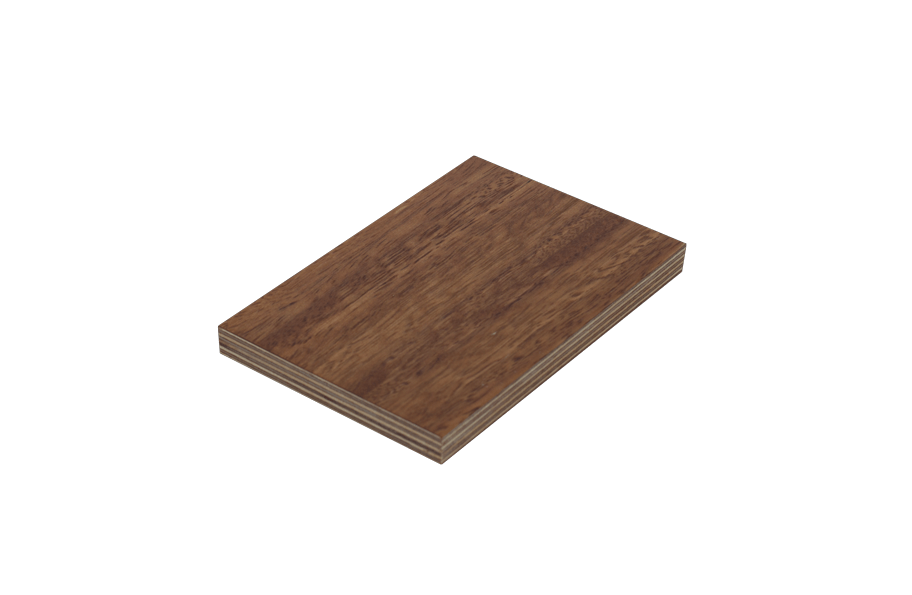

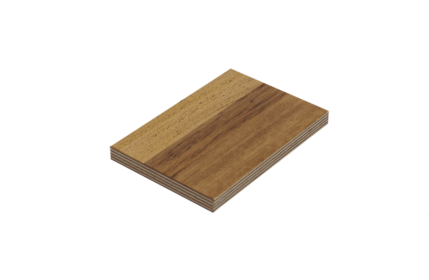

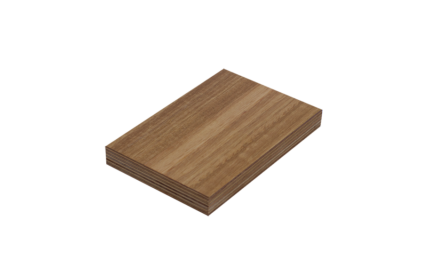

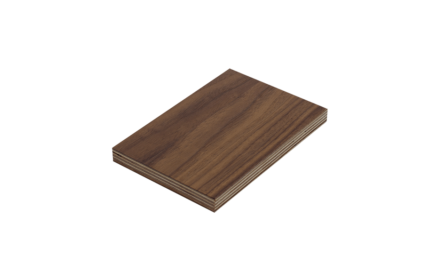

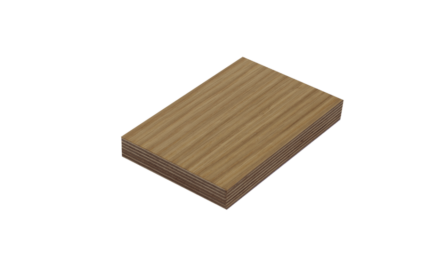

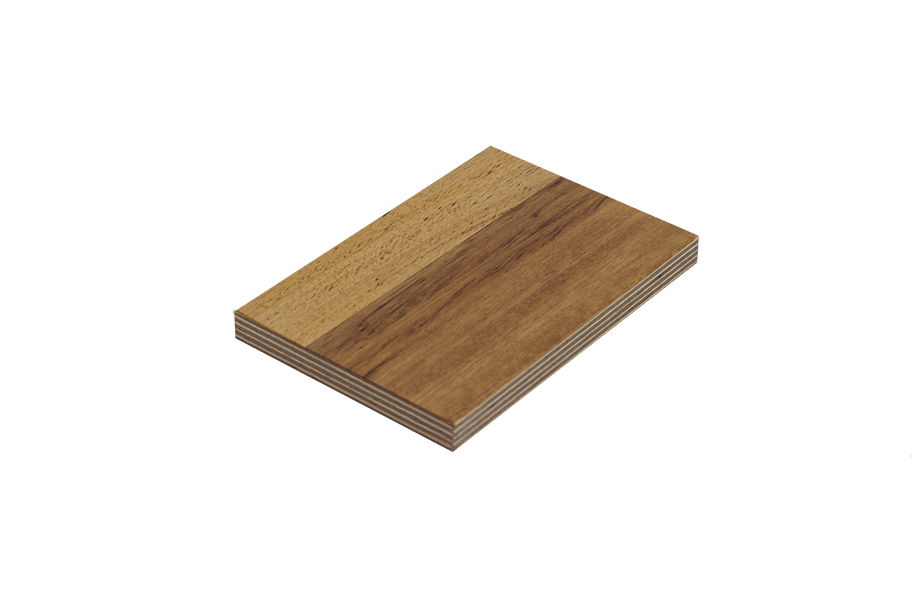

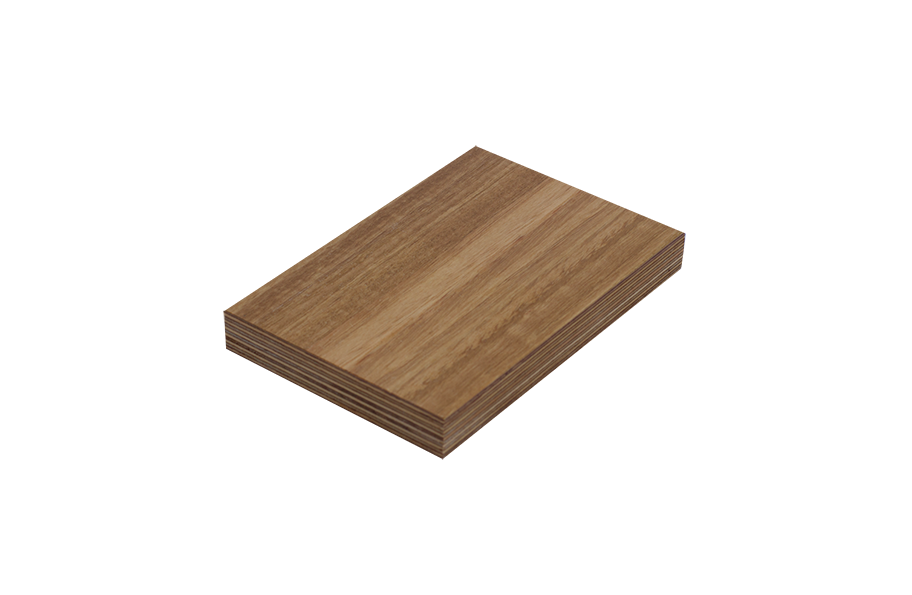

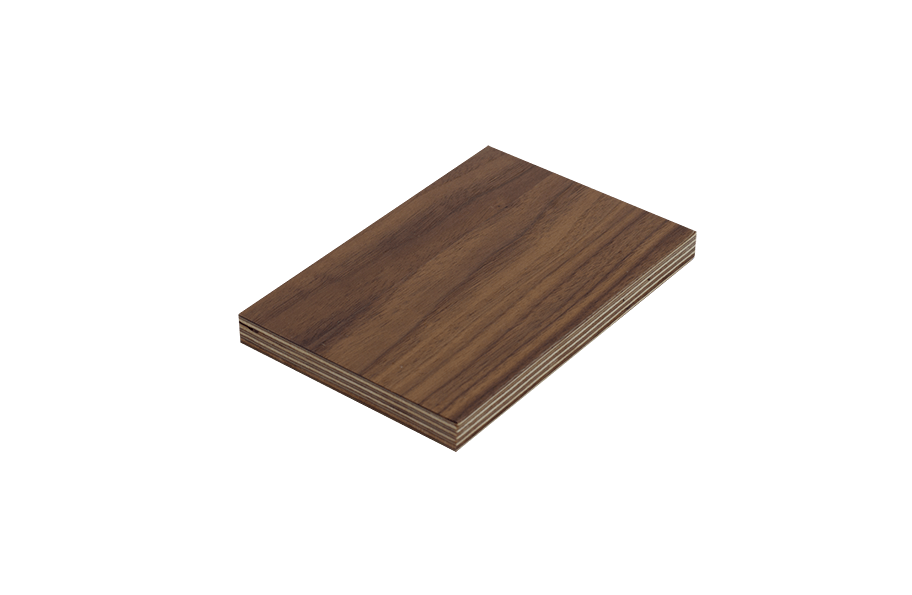

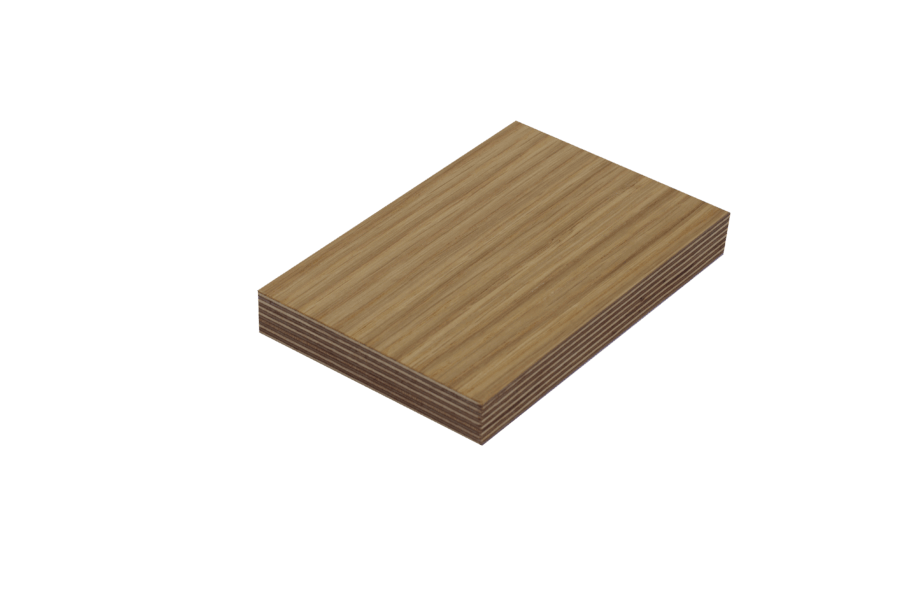

Maxi Veneer Plywood

With Maxi Veneer Plywood you can enjoy the benefits of plywood or MDF with the look and feel of solid timber. Take your pick of our six stunning plywood veneers to make your next project pop. Thanks to our state-of-the-art pressing line and pre-finishing, we can guarantee timber plywood veneers of the highest quality. Maxi Veneer also comes pre-finished with our hard-wax oil for instant installation. There’s no need to restrict Maxi Veneer to joinery projects, it looks equally impressive on large-scale wall and ceiling installations. Enjoy the richness of solid timber without the cost!

Technical Info

| Species | Spotted Gum, Blackbutt ¼ cut, Blackbutt NFG, American Oak Crown Cut, American Walnut, Plantation Oak |

|---|---|

| Substrate | Monterey Pine, Hoop Pine, Rock Maple, MR MDF & FR MDF, Okoume (Marine Grade), Baltic Birch |

| Sheet Sizes | 2400x1200mm, 3000x1200mm |

| Thickness | 12, 18, 24mm 12mm best for walls/ ceilings. 18 & 24mm best for joinery. Contact us if you have a question about your project. |

| Finish | Maxi Colour Clear Coat or otherwise specified on sample |

| Formaldehyde | E1 class |

| Lead Times | 4-10 weeks. Large quantities are worked out on a case-by-case basis |

| Min. order quantity | 10 sheets/ set- up fee for under 10 sheets |

| Warranty | 7 years. Project warranties apply. Please contact us for a project warranty certificate |

Applications

All Maxi Veneer species are suitable for both wall and ceiling linings.

Traralgon Secondary School by Clarke Hopkins Clarke: Featuring Plantation Oak Plywood Veneer. Photography by Rhiannon Slatter

Medical One by CLP Architecture: Maxi Veneer, Plantation Oak

Maxi Veneer, Plantation Oak: Donvale Christian College – Community Hub by Brand Architects Photography by Rhiannon Slatter

Veneer Plywood for Joinery

All Maxi Veneer species are suitable for joinery applications.

Maxi Veneer Blackbutt NFG. Project: Fairfield Extension Architecture & Photography Jaime Diaz-Berrio

Project: Princes Hill House with product Maxi Veneer Blackbutt NFG. Architect: Alison Dodds Architects

Project: Hargraves St with product Maxi Veneer Blackbutt NFG. Architect: Woodbeast

Project: Fairfield Extension Architecture & Photography Jaime Diaz-Berrio. Blackbutt NFG

Project: Fairfield Extension Architecture & Photography Jaime Diaz-Berrio. Blackbutt NFG

Maxi Veneer Blackbutt NFG. Project: Fairfield Extension Architecture & Photography Jaime Diaz-Berrio

Blackbutt 1/4 cut

Traralgon Secondary School by Clarke Hopkins Clarke: Featuring Plantation Oak. Photography by Rhiannon Slatter

Medical One by CLP Architecture: Maxi Veneer, Plantation Oak

Maxi Veneer, Plantation Oak: Donvale Christian College – Community Hub by Brand Architects Photography by Rhiannon Slatter

Project: Darling Square with product Maxi Veneer Spotted Gum. Architect: FJMT Architecture

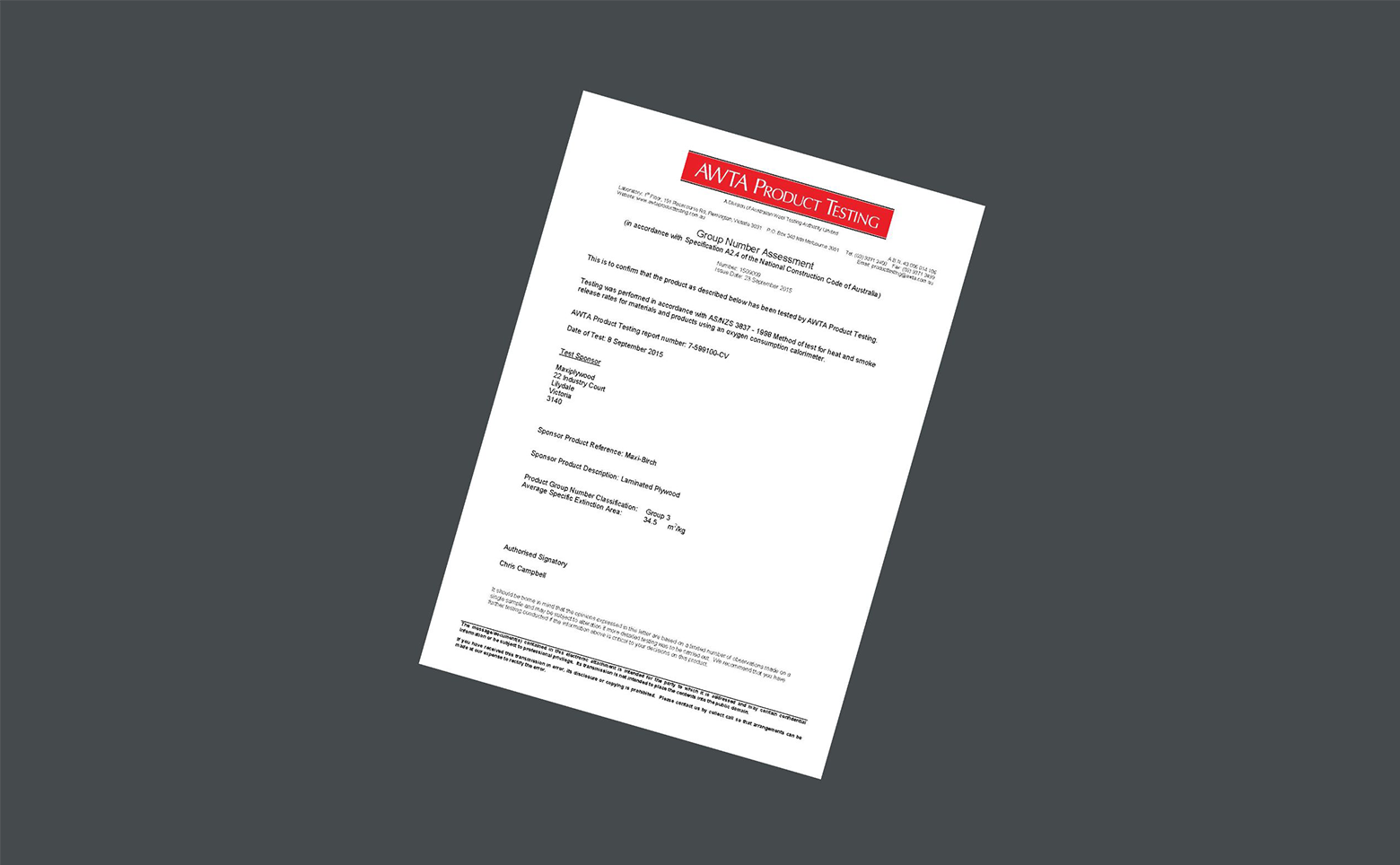

Maxi Veneer holds a standard Group 3 Fire Rating. For more information regarding our Fire Ratings, please send details of your enquiry, the project name and application details through to [email protected] and one of our friendly team will be in touch shortly.

Please get in touch for specific fire reports

Depending on your application, the best installation method for walls and ceilings using Maxi Veneer is our own Maxiply Concealed Plug or our Z- Clip system.

Learn More

Maxi Veneer can be customised in a range of forms. Custom Veneers, sheet sizes, cuts and thicknesses can be achieved.

Talk to us to help refine your specification

Baltic Birch, Monterey Pine and Baltic Pine are all FSC® Certified - FSC-C139021 products, meaning that all timber used comes from responsible forestry’s both environmentally and socially. Maxi Panel is then pre- finished in Melbourne.

Refer to our blog

Keep in mind– Maxi Veneer is manufactured in Melbourne. For maximum durability and a longer life, all edges should be sealed with a clear hard-wax oil. Tins of hard-wax oil and coloured touch up oil are available for purchase. Maxi Veneer is primarily for internal use. Maxiply does not recommend any plywood to be used for doors as external factors such as handling can affect the structure. For more information see our blog article on plywood doors.